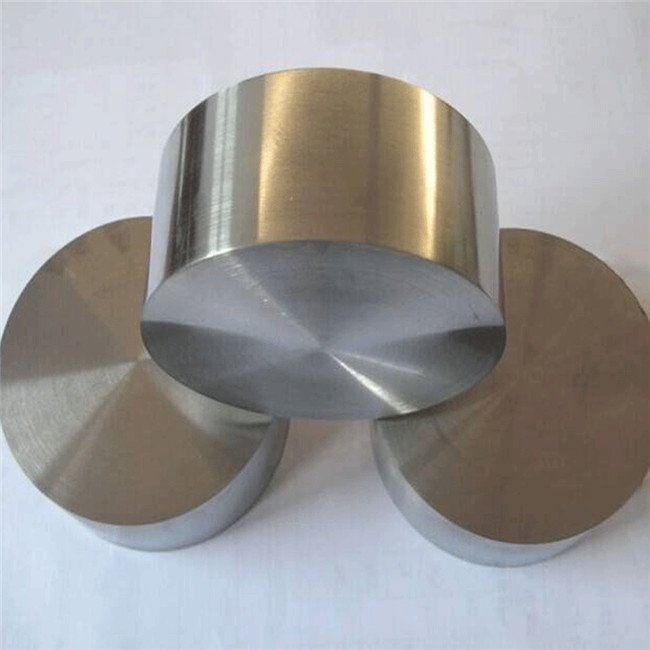

Inconel600|N06600

http://www.shlaidan.com:80/eng/detail?list=131&sid=23TIME:2022-07-21CLICK:312Product origin:

Hastelloy / SMC / SMC / VDM / metallurgy Japan

Executive standard:

ASTM B168/ASME SB-168、ASTM B166/ASME SB-166、ASTM B167/ASME SB-167、ASTM B163/ASME SB-163、ASTM B564/ASME SB-564

Main ingredients:

Carbon (c) ≤ 0.015, manganese (MN) ≤ 1.00, nickel (Ni) ≥ 72, silicon (SI) ≤ 0.5, phosphorus (P) ≤ 0.015, sulfur (s) ≤ 0.015, chromium (CR) 14.0 ~ 17.0, iron (FE) 6.0 ~ 10.0, aluminum (AL) ≤ 0.3, titanium (TI) ≤ 0.3, copper (Cu) ≤ 0.5

Physical properties:

600 alloy density: 8.47g/cm3, melting point: 1370-1470 ℃, magnetism: None

Mechanical properties:

Tensile strength: σ B ≥ 550MPa, yield strength σ B ≥ 240mpa: elongation: δ ≥ 30%, hardness ≤ 100 (HRB)

Corrosion resistance:

Inconel 600 is a nickel chromium iron base solid solution strengthening alloy, which has good high-temperature corrosion resistance (acid and alkali resistance) and oxidation resistance, excellent cold and hot processing and welding process performance, and satisfactory thermal strength and high plasticity below 700 ℃. The alloy is designed for low temperature to 1093 ℃. The oxidation resistance under high temperature is extremely excellent, and it has good oxidation resistance and carbonization resistance stability at 1093 ℃ (but in the reducing atmosphere containing hydrogen sulfide, its upper limit temperature is 535 ℃). It is very effective for the treatment of hydrogen chloride and chlorine at high temperature; Hydrogen chloride can reach about 538 ℃, and chlorine can be used safely until it reaches 510 ℃. For nitrogen, hydrogen and carburizing, this alloy also has excellent corrosion resistance, so it is used in various heat treatment furnaces.

Application fields:

Retort furnace, muffle furnace and heat treatment fixture and basket, vacuum furnace device, chlorination equipment with maximum working temperature of 1000 degrees Fahrenheit, titanium dioxide factory, retort furnace, heater, distiller, bubble cap tower and condenser in fatty acid process, evaporator tube, tube plate and tablet pressing plate in sodium sulfide manufacturing process, rosin acid treatment equipment in pulp manufacturing, etc

Supporting welding materials:

AWS a5.14 welding wire ernicr-3 or AWS a5.11 welding rod enicrfe-3 is recommended for welding inconel600 alloy

Supply style:

Plates, strips, bars, wires, forgings, light rods, welding materials, flanges, etc. can be processed according to the drawing. Welcome to inquire