2205 duplex steel | S32205

http://www.shlaidan.com:80/eng/detail?list=131&sid=34TIME:2022-07-21CLICK:55Product origin:

Ottokunp, Sweden / Nippon Steel / Nippon Steel

Executive standard:

ASTM A240/ASME SA-240、ASTM A276、ASTM A182/ASME SA-182、ASTM A312/ASMES A312

Main ingredients:

Carbon (c) ≤ 0.03, manganese (MN) ≤ 1.2, nickel (Ni) 6.0 ~ 8.0, silicon (SI) ≤ 0.8, chromium (CR) 24.0 ~ 26.0, copper (Cu) ≤ 0.5, molybdenum (MO) 3.0 ~ 5.0, nitrogen (n) 0.24 ~ 0.32

Physical properties:

2205 dual phase steel density: 7.98g/cm3, melting point: 1300-1390 ℃, magnetism: None

Mechanical properties:

Tensile strength: σ B ≥ 795mpa, yield strength σ B ≥ 550MPa: elongation: δ ≥ 15%, hardness ≤ 310 (HB)

Corrosion resistance:

2205 duplex stainless steel compared with 316L and 317L austenitic stainless steel, 2205 alloy has superior performance in spot corrosion and crack corrosion resistance. It has high corrosion resistance. Compared with austenite, it has lower coefficient of thermal expansion and higher thermal conductivity. The compressive strength of duplex stainless steel 2205 alloy is twice that of austenitic stainless steel. Compared with 316L and 317L, the designer can reduce its weight. 2205 alloy is especially suitable for the temperature range of - 50 ° f/+600 ° F. it can also be used for lower temperatures under strict restrictions (especially for welded structures).

Application fields:

Oil and gas industry equipment; Offshore platforms, heat exchangers, underwater equipment, fire-fighting equipment; Chemical processing industry, utensils and pipelines; Desalination, high-pressure RO equipment and submarine pipelines; Energy industry, such as power plant desulfurization and denitration FGD system, industrial scrubbing system, absorption tower; Mechanical parts (high-strength, corrosion-resistant and wear-resistant parts)

Supporting welding materials:

Er2209 welding wire and E2209 welding rod are selected for the welding of 2205 dual phase steel

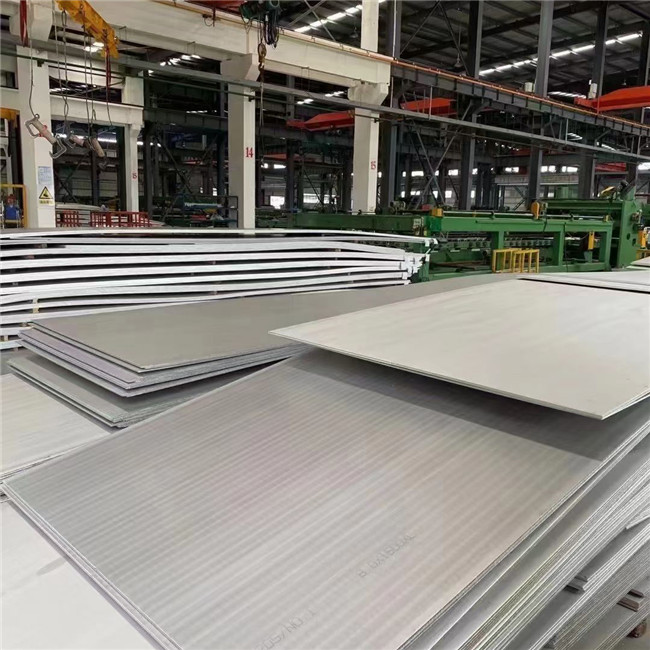

Supply style:

Plates, strips, bars, wires, forgings, light rods, welding materials, flanges, etc. can be processed according to the drawing. Welcome to inquire